Design improvements for increased durability

Echlin® VVT components are direct-fit OE replacements designed to restore engine horsepower and torque curves, reduce emissions, and restore performance. Each Echlin® VVT component is engineered with design improvements to ensure durability and performance under the most extreme conditions.

WHAT'S IN YOUR BOX?™

The Echlin® VVT Program includes more than 600 VVT Solenoids, Sprockets, Kits, and related components, making it the most comprehensive VVT Program available in the aftermarket

In addition to a full regimen of testing and analysis, each VVT component undergoes on-vehicle validation to ensure that they integrate correctly, and match designed performance in all conditions and across the RPM range

Learn more in our Echlin Professional Education Series

Premium parts start with premium components. Each Echlin® VVT component is engineered with design improvements to ensure durability and performance under the most extreme conditions

Standard Motor Products (SMP) is pleased to celebrate the 100-year anniversary of its Echlin® brand. As Echlin® celebrates 100 years, SMP recognizes its storied history, enduring partnership with NAPA®, and the milestones that have made Echlin® one of the aftermarket’s most recognized brands.

Echlin® is pleased to announce that it released more than 250 new part numbers across 31 product categories in Q3 of 2025. This includes new applications from Echlin® and NAPA® Temp for late-model import and domestic vehicles.

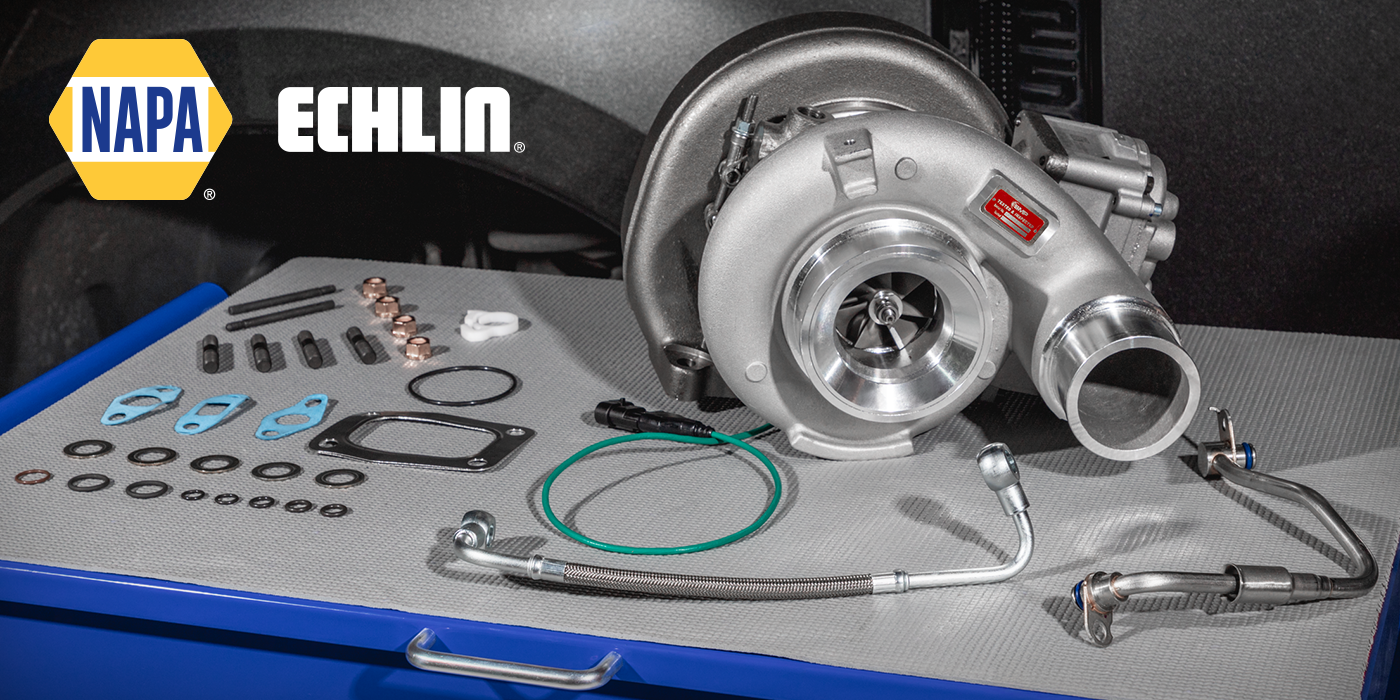

Echlin® has added to its extensive Turbocharger program with the recent introduction of Turbocharger Kits and related components for gas and diesel-powered vehicles. Echlin® New, No-Core Turbocharger Kits for import and domestic vehicles include everything needed for a complete turbo repair, including new gaskets and fasteners. All Echlin® Turbochargers are extensively tested in the lab for performance and durability and undergo on-vehicle testing at SMP’s Testing Center in Texas.

Echlin® is pleased to announce that it has released new part numbers across 35 product categories in Q2 of 2025. This includes new applications from NAPA® Echlin® and NAPA® Temp. New coverage for late-model import and domestic vehicles was added across multiple powertrains.

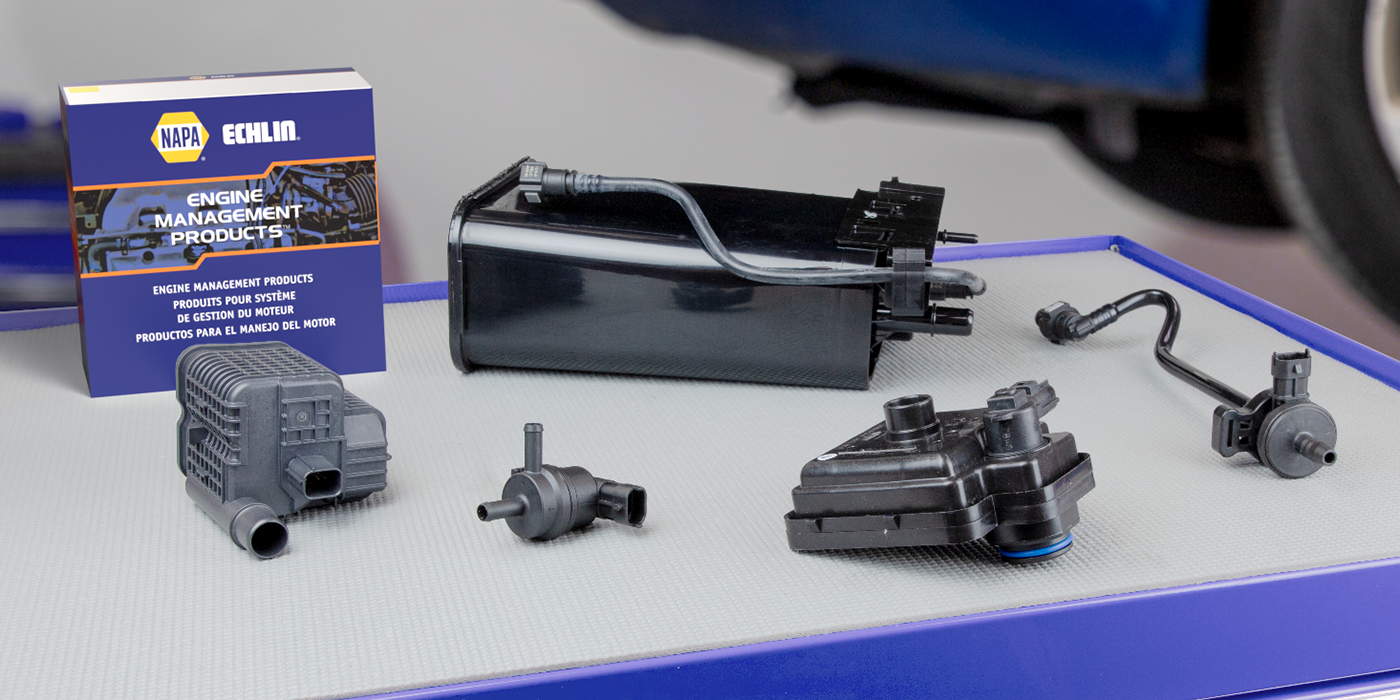

Echlin® has expanded its comprehensive Evaporative Emissions (EVAP) program with the recent introduction of more than 40 new EVAP applications. The Echlin® EVAP program is the most complete in the industry with more than 1,200 part numbers, from the most popular Canister Purge Solenoids to several hard-to-find Canister Purge Hoses.

Echlin® continues to add to its growing Electronic Parking Brake Actuator program. Parking brake actuators are one of the fastest-growing categories in the automotive aftermarket, and Echlin® offers industry-leading coverage for import and domestic vehicles.

Echlin® is pleased to announce the continued expansion of its line of Tech Expert® Oil Filter Housing Kits and Assemblies. Tech Expert® Oil Filter Housing Kits feature design improvements over the OE units, are application-specific, not universal, and are assembled from the factory with the sensors and oil filter already installed, and include new hardware and manifold gaskets.

Echlin® continues to add to its line of solution-driven Kits. Echlin® and Tech Expert® Kits include everything technicians need for a complete repair. More and more technicians are looking for complete repair solutions, and Echlin® has them covered.

Echlin® is pleased to announce that it released a total of 2,367 new part numbers in 2024, including introductions from NAPA® Echlin® and NAPA® Temp. New coverage for late-model import and domestic vehicles was added across all powertrains, including advanced internal combustion engine (ICE), hybrid and electric.

Echlin® continues to expand its industry-leading ABS Sensor program, which now includes nearly 2,500 SKUs for import and domestic vehicles. Echlin® ABS Sensors are designed for accuracy, speed and durability, and are tested to ensure that they match OE voltage output, resistance and trigger wheel gap.

Echlin® has expanded its extensive Collision Repair program, which now includes 8,000+ parts. Echlin’s program includes Advanced Driver Assistance System (ADAS) components, underhood and cabin components, actuators and sensors, and connectors. Component are direct-fit replacements, extensively tested, and designed to integrate with the electronic safety systems found on today’s vehicles. Leading coverage in key ADAS and collision repair categories means technicians can spend less time looking for parts, and get their customers back on the road.

Echlin® is pleased to announce that it has recently released 120 new part numbers. The most recent releases provide new coverage in a variety of key product categories with coverage for late-model import and domestic vehicles through the 2024 model-year.

Echlin® and NAPA® Temp are dedicated to expanding product offerings for advanced driver assistance systems, advanced internal combustion engines, and other popular vehicle control and temperature control categories.

Echlin® is pleased to announce the continued expansion of its industry-leading Ignition Coil program. Echlin® offers more than 700 Coils, with new numbers added each month. Each Echlin® Coil is subjected to extensive testing and product validation, and popular Coils are available in multi-packs for a complete coil service.

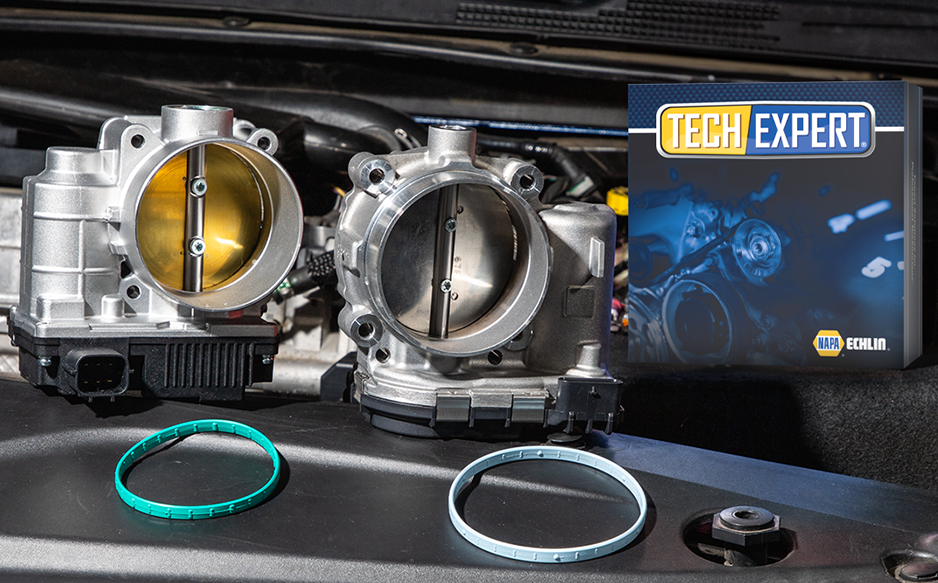

Echlin® continues to expand its industry-leading Tech Expert® Electronic Throttle Body (ETB) program. Echlin® is an expert manufacturer with nearly 250 ETBs and new numbers being introduced each month. Every Tech Expert® ETB is 100% new, never remanufactured, and is fully calibrated and tested for precise performance.

Echlin® is pleased to announce that it has released 334 new part numbers in its July new number announcement. This most recent release provides new coverage in 115 distinct product categories and 182 part numbers for 2023 and 2024 model-year vehicles.

Echlin® is pleased to announce that it has released 186 new part numbers in its June new number announcement. This most recent release provides new coverage in 58 distinct product categories and 45 part numbers for 2023 and 2024 model-year vehicles.

Echlin® continues to expand its industry-leading Variable Valve Timing (VVT) program. The program already offers more than 600 part numbers for import and domestic vehicles, with new numbers added each month. Echlin® VVT components are developed and tested in-house, and include design improvements to address OE flaws.

Echlin® is pleased to announce that it has released 200 new part numbers in its May new number announcement. This most recent release provides new coverage in 60 distinct product categories and 75 part numbers for 2023 and 2024 model-year vehicles.

Echlin® continues to expand its industry-leading Camshaft and Crankshaft Position Sensor program with late-model coverage for import and domestic vehicles. Echlin® Cam and Crank Sensors are engineered for accuracy, speed, and durability to help keep vehicles operating as designed and last.

Standard® Cam & Crank Sensors are end-of-line tested for timing, pulse width, and signal amplitude so they can be installed with confidence.

It’s this attention to detail that ensures every Standard® and cam and crank sensor are the most consistent and durable camshaft and crankshaft sensors in the industry.

That's what is in our box. What’s in your box?™

Echlin® has announced the introduction of 268 new part numbers in its April new number announcement. This most recent release provides new coverage in 75 distinct product categories and 80 part numbers for 2023 and 2024 model-year vehicles.

Echlin® has announced the introduction of 123 new part numbers in its March new number announcement. This most recent release provides new coverage in 53 distinct product categories and 47 part numbers for 2023 and 2024 model-year vehicles.

Echlin® is pleased to share the expansion of its line of Oil Filter Housing Kits. Tech Expert® by Echlin® Oil Filter Housing Kits feature design improvements over the OE units, are application-specific, not universal, and come completely assembled from the factory for a drop-in solution.

Echlin® is pleased to announce the introduction of 118 new part numbers in its February new number announcement. This recent release provides new coverage in 57 distinct product categories and 55 part numbers for 2023 and 2024 model-year vehicles.

Echlin® is dedicated to expanding its comprehensive Emission Control program. NAPA® Echlin’s Emission Control program includes evaporative emission control (EVAP), exhaust gas recirculation (EGR), and positive crankcase ventilation emission control systems. With more than 3,500 part numbers, NAPA® Echlin® offers the most complete program in the industry, with everything needed for a complete repair.

Echlin® is pleased to announce the introduction of 208 new part numbers in its January new number announcement. This most recent release provides new coverage in 72 distinct product categories and 115 part numbers for 2022, 2023, and 2024 model-year vehicles.

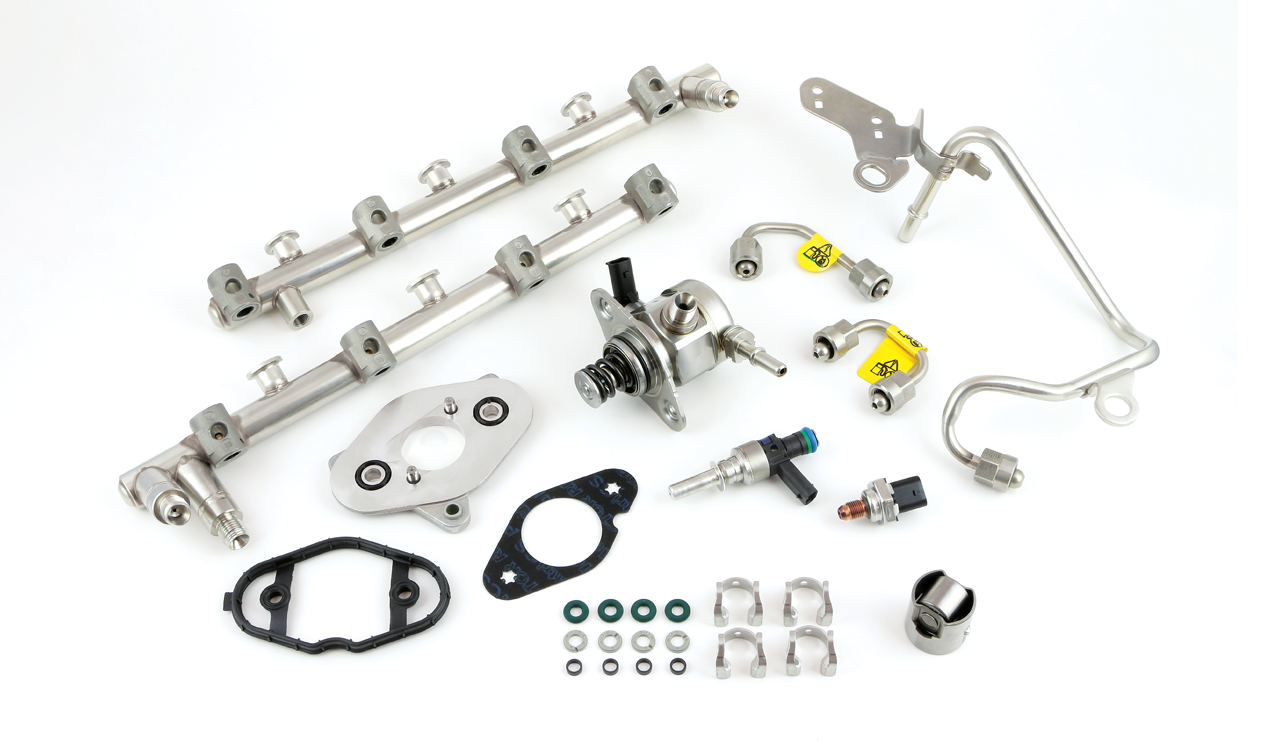

Echlin® continues to expand its aftermarket-leading Gasoline Fuel Injection program. With more than 2,100 part numbers, NAPA® Echlin® offers the most complete program in the industry, including everything needed for a complete repair.

Echlin® is pleased to announce that it released a total of 2,626 new part numbers in 2023. Closing out the year, Echlin® has released 227 new part numbers in its December new number announcement. This most recent release provides new coverage in 71 distinct product categories and 128 part numbers for 2022, 2023, and 2024 model-year vehicles.

Echlin® has released 276 new part numbers in its October new number announcement. This most recent release provides new coverage in 113 distinct product categories, and 118 part numbers for 2022, 2023, and 2024 model-year vehicles.

Echlin® continues to expand its line of Oil Filter Housing Kits. Since the program’s introduction, Echlin® has added coverage for many popular applications.

Echlin® is pleased to announce the expansion of additional categories covering import and domestic vehicles with ICE, hybrid, and electric powertrains. As the car parc evolves, Echlin® remains dedicated to introducing and expanding new product lines to provide technicians with the parts needed to do the job right, regardless of powertrain. When OE fails, technicians trust Echlin® to deliver precision components that keep a wide variety of systems operating as designed.

Echlin® has released 272 new part numbers in its September new number announcement. This most recent release provides new coverage in 89 distinct product categories, and 115 part numbers for 2022, 2023 and 2024 model-year vehicles.

NAPA® Echlin® continues to expand its aftermarket-leading Gasoline Direct Injection (GDI) program. GDI technology has been an integral part of helping to improve fuel economy while reducing emissions, and can be found on more than half of the U.S. fleet.

The most recent expansion to NAPA® Echlin’s Tech Expert® ETB offering features applications for popular import nameplates including Toyota, Nissan, Mazda, Hyundai, and Kia. Tech Expert® ETB line-up now includes more than 200 part numbers, and covers 190 million vehicles. Providing industry-leading, late-model coverage for domestic and import vehicles, Tech Expert® offers ETBs for 2021 and 2022 model years.

The New Multi-Frequency TPMS Sensor combines 314.9, 315, and 433/434 MHz applications into one single SKU, eliminating a duplication of customer inventory. The Single Sensor program is an addition to NAPA Echlin’s QWIK-SENSOR® Universal Programmable TPMS Sensors and OE-Match TPMS Sensors and provides coverage for more than 200 million vehicles-in-operation (VIO) in North America.

Check out how our sensors protect against over-voltage, under-voltage, reverse-voltage, and short circuits, and maintain accuracy during heavy-duty shock, vibration, and maximum temperature conditions.

Eric Sills, President and CEO of Standard Motor Products and incoming Board Chairman of AASA, spoke before the U.S. House of Representatives Committee on Energy & Commerce Subcommittee on Consumer Protection & Commerce. Sills was one of only four to testify on supply chain resilience and American competitiveness.

With a long history of design innovation, NAPA® Echlin’s product expertise and manufacturing capabilities are vital assets in making Belden® EDGE the most trusted name in spark plug wires.

Every time you take a NAPA® Echlin® part out of the box, you know you are holding in your hands the very best. Quality, durability, reliability, extensive testing…that’s what’s behind NAPA® Echlin® parts.

Auto manufacturers receive as much as 25GB of data per hour from your vehicle and get to decide where that data goes. Access to vehicle data is mission critical for us. That’s why we are working with the Auto Care Association and Automotive Aftermarket Suppliers Association (AASA) to raise consumer awareness of this issue and support industry advocacy efforts. Help us protect our industry and ensure consumer choice.

It’s Your Car. Your Data. And it should be Your Choice.

GM’s Vortec engines come with a Sequential Port Injection System (SCPI). NAPA Echlin’s Multi-Port Fuel Injection (MFI) system has several advantages over the original Sequential Central Port Injection (SCPI) system, including port fuel delivery and high reliability, better hot starts and reduced vapor emissions, and faster prime on hot restarts.

To account for the burgeoning diesel market, we have fully invested in diesel. Today, NAPA® Echlin® Diesel offers thousands of diesel parts across hundreds of unique diesel categories for popular applications including medium-duty trucks.

Our latest installation video shares helpful tips on replacing the Multiair PCV Valve on a Chrysler vehicle with a 2.4L engine. You can always count on NAPA Echlin to help you solve your automotive problems.

Do you have an idea for a part that we should offer? We want to hear from you directly.