-

What's In Your Box

- History, Trusted Brands & Training

- Manufacturing, Engineering & Testing

- ABS Speed Sensors

- ADAS

- Blower Motor Resistors

- Camshaft & Crankshaft Sensors

- Collision Repair Program

- Electronic Throttle Bodies

- EV / Hybrid Program

- EVAP Components

- Gas Fuel Injection

- GDI Injection

- Ignition Coils

- NAPA Echlin Import Coils

- NAPA Echlin Kits

- Oil Filter Housing Kits

- Oil Pressure Switches

- Parking Brake Actuators

- TPMS

- Turbocharger Kits

- Variable Valve Timing

- Resources

- More than 2500 SKUs and 96% coverage for domestic and import applications

- ABS sensors perform flawlessly, matching the OE for form, fit and critical function

- Superior quality control with extensive laboratory and real-life ABS sensor testing

All NAPA® Echlin® ABS Sensors are premium quality and engineered to perform like the original.

NAPA® Echlin® ABS Speed Sensors are designed to provide consistent performance, matching the OE for form, fit and precision function. Features such as superior magnetic circuit materials are engineered into our sensors to deliver higher voltage output preventing ABS system failure.

Superior design is one reason NAPA® Echlin's ABS sensors perform equal to or better than the original.

A Closer Look: NAPA® Echlin® ABS Speed Sensors

ABS Sensor Testing

Rigorous Testing Means a More Reliable Sensor

Extensive laboratory and real-life testing includes evaluating the following:

- Shaft speed vs. delta voltage

- Output voltage and variation to OE

- Magnetic field strength and air gap

- Output wave form and pulse width

How Does the Competition Measure Up?

The competition didn’t physically match up. It measured 29-51% lower voltage output when compared to the GM sample, leading to potential system failure. In the Ford test, the competition measured 45-74% lower voltage, with resistance and inductance flaws that result in poor performance.

NAPA® Echlin® ABS sensors delivered a more consistent signal output performance, matching OE for output voltage, resistance and all critical measurables.

We include the quality and extras you need to ensure a proper install.

The anti-lock braking system uses an ABS or wheel sensor to monitor the wheel speed and send this information to the ABS computer. The ABS computer uses this information to prevent the brakes from locking during a stop.

-

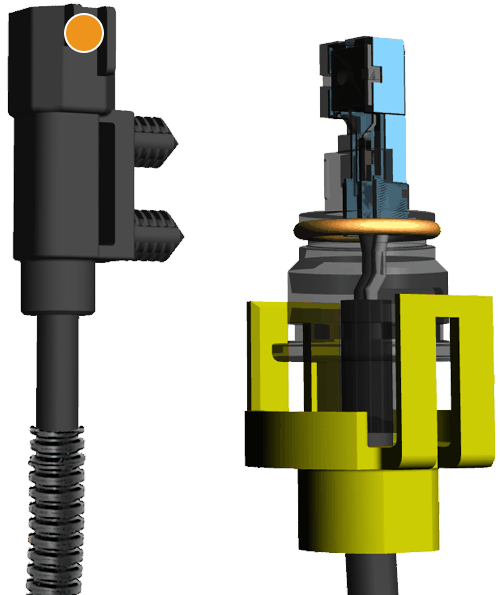

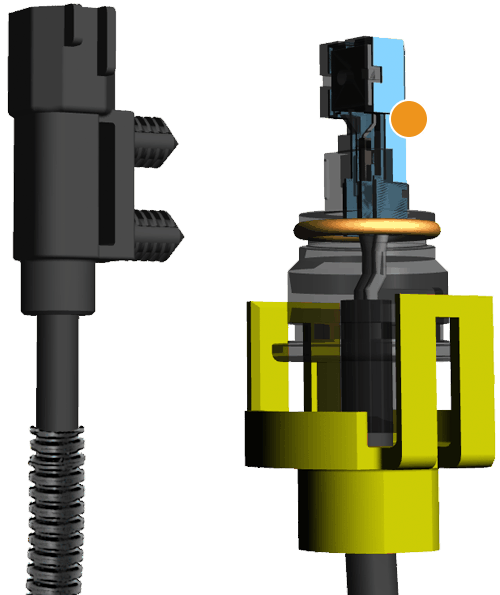

OE connectors and terminals ensure accurate, water-tight connection to the engine wire harness.

-

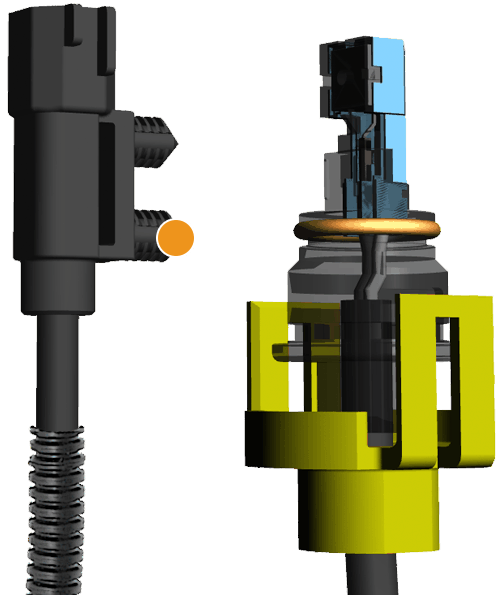

Grommets and wire clips are included on the harness to ensure proper mounting and routing within the vehicle chassis.

-

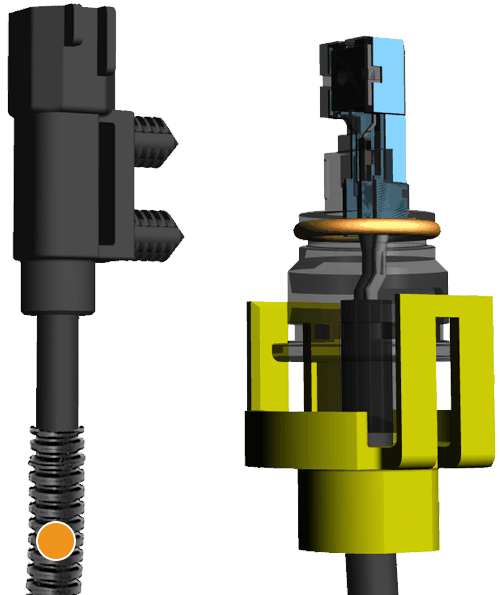

Wire harness comes with protective sleeve to prevent wires from chafing and creating short circuits.

-

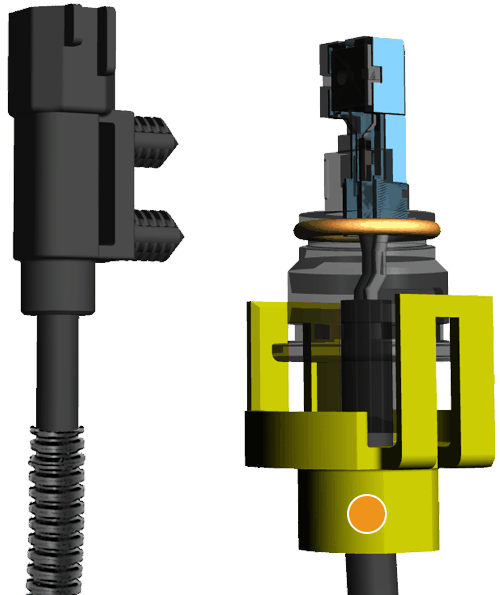

Sensors are 100% tested for proper functionality.

-

Sensor housing is made from high-quality, glass-reinforced plastic resin to withstand high temperature and environmental conditions.

Tech Tip: Test Non-Hall Effect Sensors

On non-Hall effect sensors, you can use an ohm meter to test ABS sensor wire windings and harnesses for opens, shorts and proper factory-specified resistance.

NAPA® Echlin® ABS Wheel Speed Sensors Vs. The Aftermarket Competition

The NAPA® Echlin® 531339 uses microsensors to produce the unique forward and reverse signals that modern vehicles require to keep electronic safety systems (Hill Hold Assist, ESC and Automated Braking) working correctly.

The NAPA® Echlin® Multi-Directional ABS Wheel Speed Sensor was tested on a 2020 Toyota Tacoma against 7 other sensors. Only NAPA® Echlin® passed.

Multi-directional ABS wheel speed sensors from the NAPA® Echlin® aftermarket competitors can't measure vehicle direction.

These sensors don't give the ECU enough information, potentially disrupting electronic safety systems.

For nearly 100 years, when the OE failed, technicians have trusted NAPA® Echlin® to deliver a part that’s equal to or better than the original it’s replacing.