NAPA Echlin Innovations

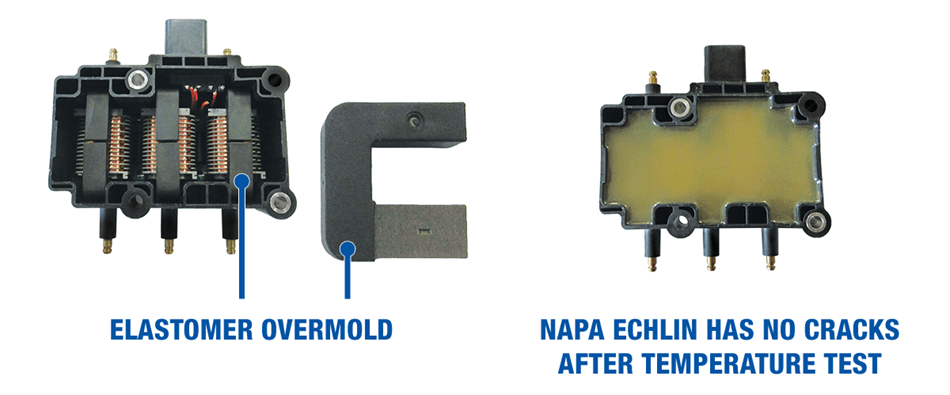

Elastomer Overmold

OEM Problem: The OE polypropylene cover on steel core leads to epoxy cracking, moisture intrusion, degraded performance and eventual coil failure.

NAPA Echlin Solution: The NAPA® Echlin® design overmolds the iron core with TPE elastomer preserving coil integrity, resulting in no cracks after thermal cycle testing.

Source: NAPA Echlin Poland Testing Lab, 2018

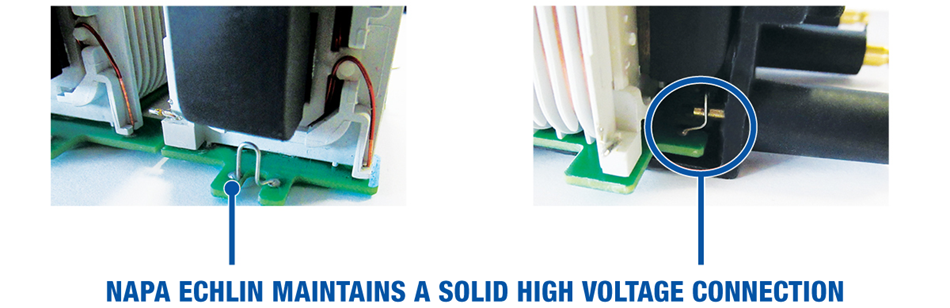

Spring Terminal Design

OEM Problem: The OE metal terminal deforms while the epoxy cures causing the high voltage connection to fail.

NAPA Echlin Solution: NAPA® Echlin® engineering features a spring terminal design to maintain a solid high voltage connection for top performance and long service life.

One-Piece Design, No O-ring

OE Design Flaw: O-ring Design

When the OE O-ring breaks down it allows moisture intrusion which impedes performance and shortens coil life.

NAPA Echlin Solution: Eliminate O-ring Housing

The NAPA® Echlin® one-piece design with no O-ring housing prevents moisture intrusion, ensuring peak coil performance and long service life.

SMP designs improvements to numerous OE pencil coils