Ignition Coil Breakdown and Testing

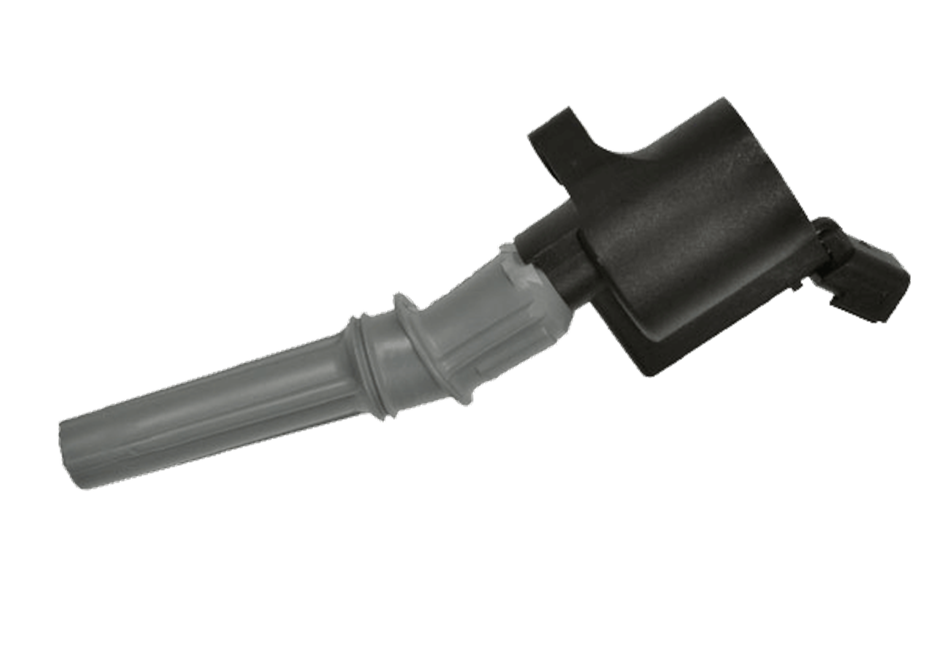

Coil-on-Plug Breakdown

A coil-on-plug is designed to perform the functions of the ignition coil (creating the spark energy) and the spark plug wire set (containing and delivering the high voltage energy to the spark plug). To ensure proper function, NAPA® Echlin® Coil-on-Plug Assemblies feature premium-quality components.

Designed using advanced thermoplastics to ensure proper connection and resist fractures caused by heat and thermal cycling

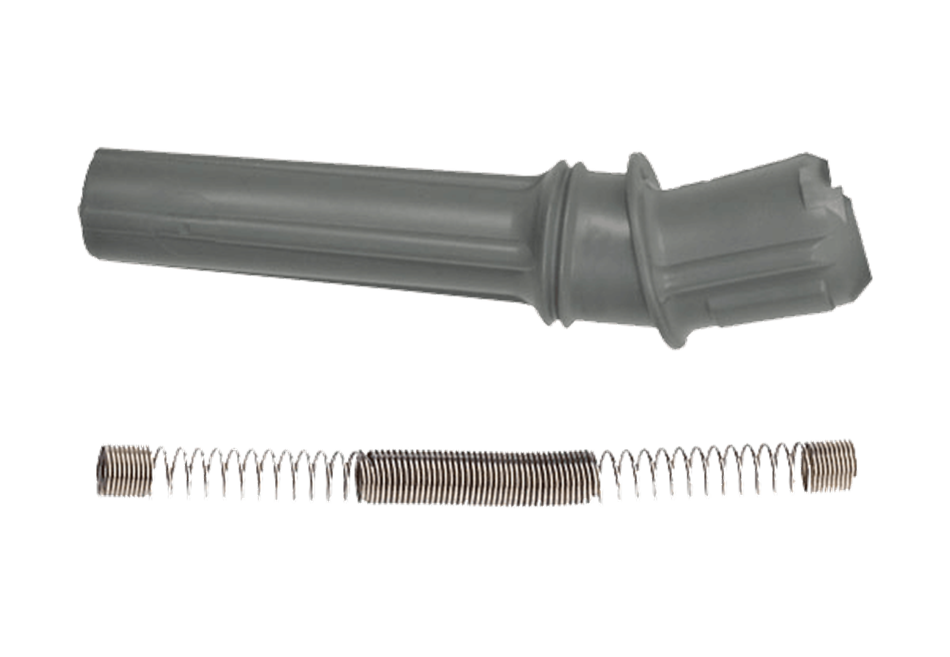

High-temp boot prevents highvoltage leaks, while stainless steel spring with internal ferrite noise suppressor prevents radio frequency interference (RFI)

High-impact material bonds extremely well to epoxy to ensure longer life in all operating conditions

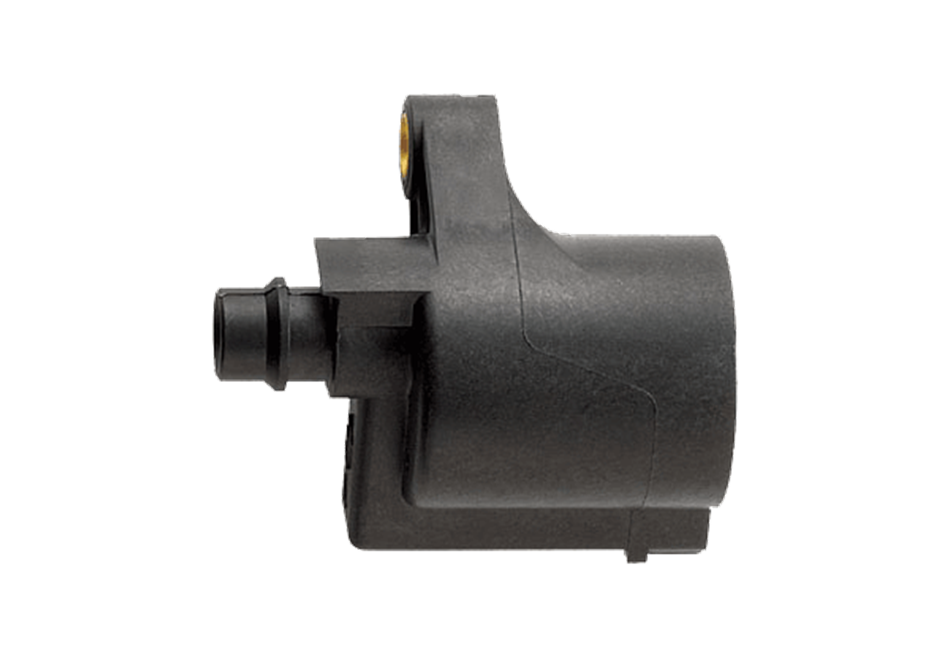

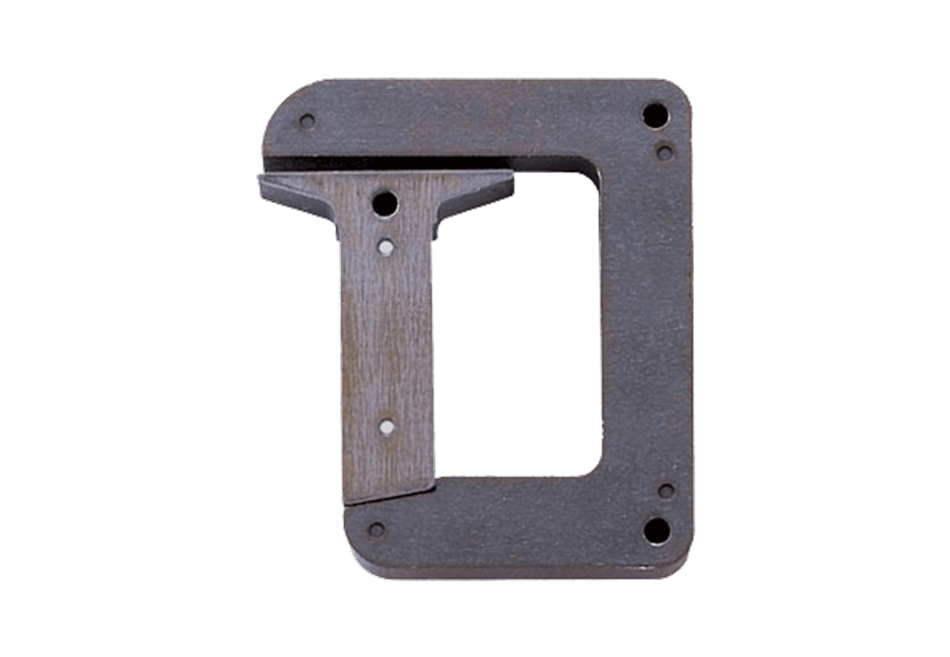

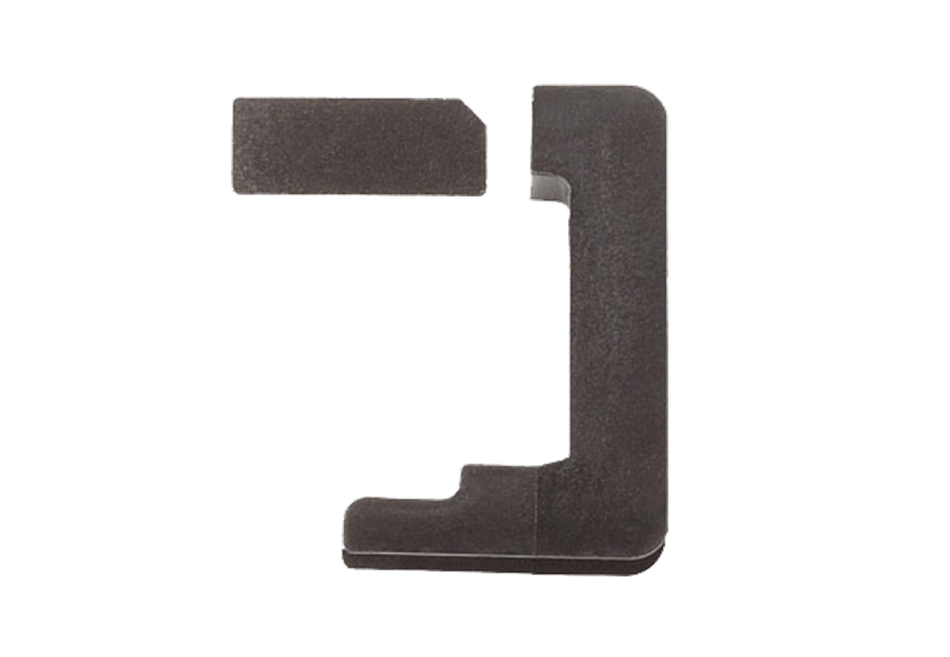

Internal neodymium permanent magnet surrounded by grainoriented magnetic-laminated steel maximizes high-voltage output at all speeds

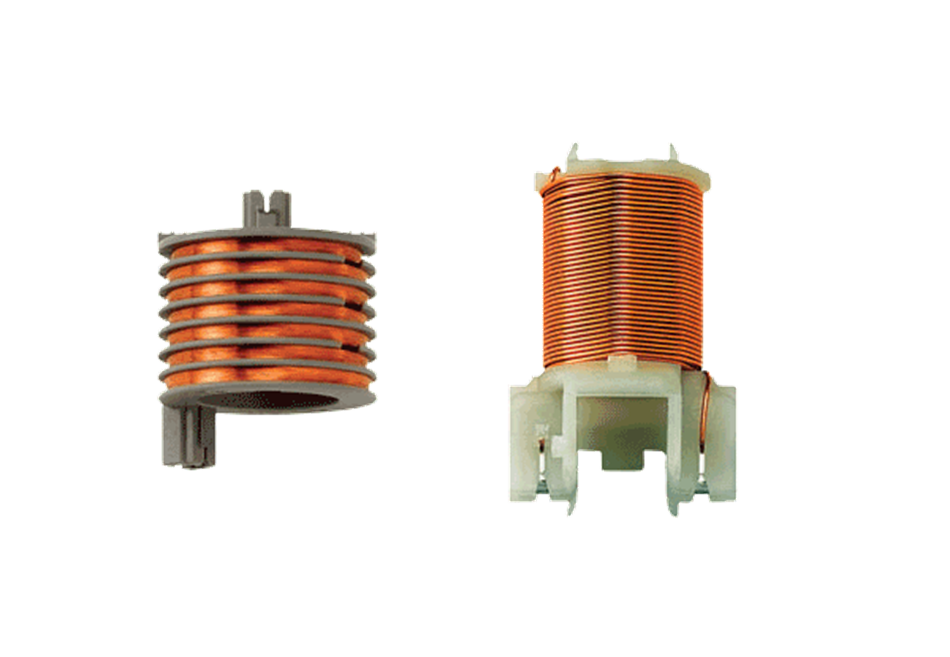

Primary (25 gauge) and Secondary (43 gauge) copper wire ensure high-voltage availability for peak performance while reinforced bobbins prevent voltage flashover for extended service life

Manufactured using high-voltage resistant thermoplastics to prevent premature coil failure

"As testing shows, we’ve designed our NAPA Echlin Ignition Coils for superior performance and durability under the harshest conditions."

Tomasz Michalik

Technical Director - NAPA Echlin Bialystok, Poland

Coil-on-Plug Testing

We performed an extensive engineering analysis of OE DG500 and DG508 to NAPA® Echlin®. The engineers measured winding resistance, inductance and output voltage, spark, energy, waveform peak voltage and ringing, as well as a complete physical and sectioned comparison to OE.

| WINDING RESISTANCE / INDUCTION AND OUTPUT VOLTAGE / SPARK ENERGY | |||||||

| Primary | Secondary | Output Voltage | Spark Energy | ||||

| Resistance | Inductance | Resistance | Inductance | 50pf | 60 Hz | 60 Hz | |

| Part no. | (mohms) | (mH) | (kohms) | (H) | (Peak kV) | (mV-S) | (mJ) |

| NAPA® Echlin® IC386 | 492 | 1.53 | 5.36 | 9.59 | 25.2 | 3.70 | 29.6 |

| NAPA® Echlin® IC369 | 489 | 1.49 | 5.28 | 9.47 | 25.2 | 3.74 | 29.9 |

| Average NAPA® Echlin® | 491 | 1.51 | 5.32 | 9.53 | 25.2 | 3.72 | 29.8 |

| OE DG500 | 515 | 1.63 | 5.55 | 8.61 | 24.4 | 3.72 | 29.8 |

| OE DG508 | 511 | 1.58 | 5.50 | 8.19 | 24.2 | 3.69 | 29.5 |

| Average OE | 513 | 1.61 | 5.53 | 8.40 | 24.3 | 3.71 | 29.7 |

The Findings

NAPA® Ignition Coils look, fit and perform like the original they replace with 100% end of the line production testing. The NAPA® coils also provide an improved secondary winding design (additional winding bays) that helps prevent internal arcing and high-voltage breakdown.

- The NAPA® coils tested 3.7% higher than OE in output voltage.

- The NAPA® coils were equal to OE in spark energy.

- In waveform testing, NAPA® coils’ peak output voltage was about 1000 volts higher than OE.

- The NAPA® coils had a longer spark duration than the OE, resulting in more energy supplied to the spark plugs.

The NAPA® coils match or exceed the OE coils in all categories and are an excellent replacement exceeding the OE performance.